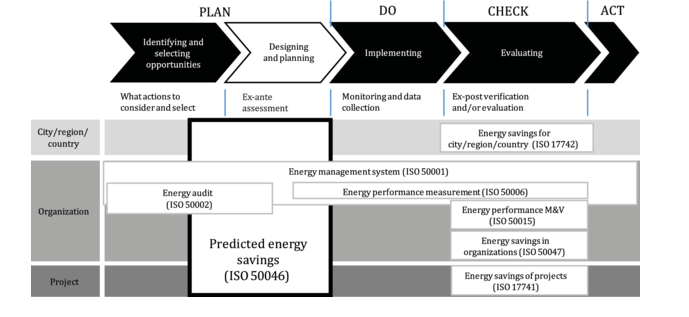

Chapter 6. Planning

Actions to address risks and opportunities

In essence, this chapter is concerned with exploring the context of external and internal issues and determining the stakeholders and their expectations.

Objectives, energy targets and planning to achieve them

Following the requirements of ISO 50001, documented objectives must be defined for all relevant functions, levels, processes, systems, and, if applicable, locations. Besides, the company must define energy objectives and put them in writing. The statements in the appendix to the standard are indicative but not binding.

Energy objectives and targets must be consistent with the energy policy formulated. The energy objectives and goals must be SMART, that is, measurable, take into account the applicable requirements, take into account the SEU, oriented to opportunities, must be monitored, updated, and communicated.

It is not always possible to set specific energy targets. For example, it is impossible to predict if the proposed solution will be successful or if the corresponding energy data is missing. In these cases, project targets are preceded by quantified energy targets.

Projects are primarily concerned with the influence of the way systems are operated, temperature conditions for heating or cooling, system configuration, age, and the nature of comparable systems, product groups, or individual products on energy consumption. They provide essential insights into the extent to which energy targets are qualitatively feasible.

Projects/goals should always assign specific responsibilities and project steps with good project management requirements. In ISO 50001:2018, the following requirement is set out in section 6.2.3 of the standard:

- Energy goals/targets

- measure

- Resources in person-days/€

- responsibility

- deadline

- Verification method

- identification number

In practice, it isn't easy to formulate objectives. Reasonable energy-saving projects often run into financial hurdles. This is referenced in ISO 50001. Goals must be ambitious and follow essential energy aspects. However, they must also be tailored to the financial capacity of the company. It is not easy to weigh the objectives' suitability, so the objectives must be transparent in the energy management team in terms of their cost-benefit relation to illustrate the advantages of investments and their limits to the decision-taking holders.

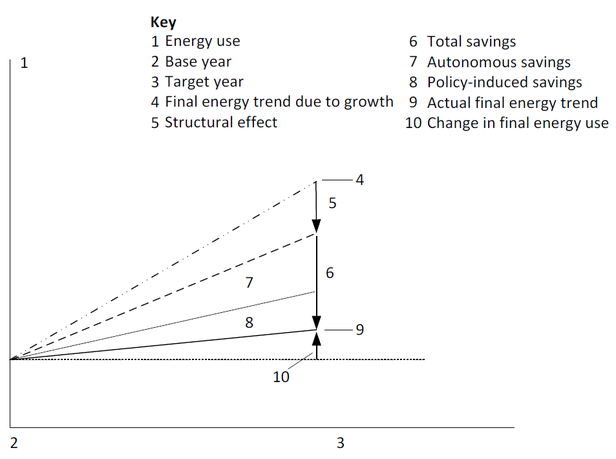

Energy review

As proof of this, it is stated that the organization itself determines the criteria of what it considers essential. Meteorological factors, operating conditions such as interior temperature, light intensity, working hours, and production volume are cited as examples. In other words, the question arises: What are the factors that influence this energy consumption? They can be temperature influences, but different raw materials are also thought about concerning their production influence. Different product properties (e.g., layer thicknesses, consistency) can also affect energy consumption. This means that you can no longer avoid breaking down energy consumption across different products or at least product groups to identify improvement approaches.

A "normalization" then takes place, that is to say, "A modification of the data taking into account the changes to allow the comparison of energy performance under equivalent conditions." Absolute power consumption is not significant. With production fluctuations, energy consumption increases. From this, it cannot be determined to what extent an improvement or deterioration in energy efficiency is associated with this.

As a result, developments and comparisons must be made with specific key figures (section 6.4.). According to the standard, the current energy output must be determined for each SEU. Energy performance is understood as the following: Energy performance corresponds to measurable energy efficiency results or measurable energy consumption results related to energy use or the energy input base. The energy assessment and the description of the procedure used for it is part of the necessary documented information in the EnMS.

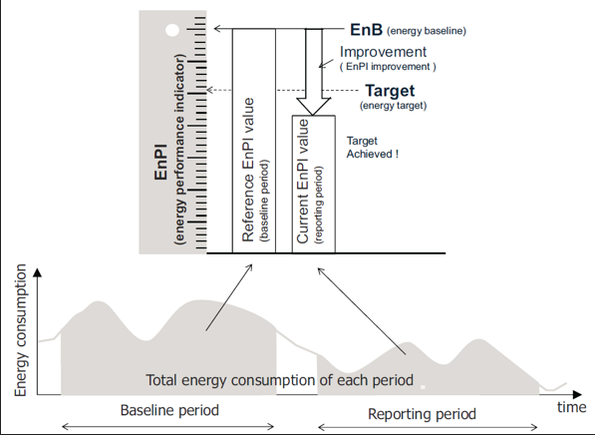

Energy performance indicators

The absolute energy consumption measured does not yet provide any evidence of an improvement in energy performance. As a result, organizations use specific ratios, so-called Energy Performance Indicators. However, be careful with specific ratios. These do not consider baseload and non-linear effects of energy use; its use will be misleading for installations with a large baseload. The choice of its energy performance indicators, EnPIs, is left to each organization as its own. These depend essentially on: selection based on user requirements and organizational complexity. It is crucial that the significant energy users, SEUs, are the base for the EnPIs. Important influence factors (relevant variables) that affect energy-related performance must also be taken into account, and the procedure for selecting EnPIs should be kept as documented information. Documented information must also be available for EnPIs values.

The point is not to create a confusing multitude of energy indicators. As already mentioned, the critical energy figures mainly revolve around SEUs. Other key energy indicators can be developed to obtain new energy-relevant findings. They can have a temporary value and can later be disregarded.

Energy baseline

The energy baseline must allow a reasonable period of time. An appropriate period means that the organization considers operating cycles, regulatory requirements, or variables that affect energy consumption and energy efficiency so that the data period adequately represents a full range of performance. The reporting and reference period should be long enough to allow interpretations to be made. Usually, this is 12 months. However, longer periods of time are also conceivable for establishing seasonal connections. Shorter periods should be selected if the processes are stable and unaffected by external factors and are always recurring. Of course, a direct comparison between energy consumption and the reference period is only possible if there has not been a significant change in the relevant variables. To compare energy performance between two periods, the EnPI and the corresponding energy starting point must be normalized using relevant variables.

For this, the following fundamental distinctions must be made: Specific energy consumption can be calculated for a single essential relevant variable and a small baseload. In the case of several relevant variables or a high base load, a model is used that describes the relationship between energy consumption and the relevant variable.

ISO 50006 Appendix D contains more information on the standardization of EnPIs and EnBs using relevant variables.

Planning for collection of energy data

Planning should include at least the following aspects:

- Relevant variables

- SEUs

- power consumption

- Operational criteria

- Dates set in action plans.

The required planning of data collection should be checked at regular intervals and adjusted if necessary. Other requirements for data collection are

- Accuracy,

- Reproducibility, and

- Redundancy.

In addition to using appropriate methods, the measurements' success is measured, and their informative value regarding the suitability and qualification of the measurement personnel employed is measured. This standard establishes requirements to measure personnel. The following criteria include:

- Competence of measurement personnel

- Experience in handling measurement technology

- Impartiality

- Reliability

- Confidentiality.

Planning should include requirements for the precision of measurements and address possible measurement uncertainties. Plans should be designed to have a high level of

- Transparency

- Understandability

- traceability, and

- reproducibility.

This means that

- The methods are sufficiently described (and not only transparent to a few employees),

- good practices (recognized methods) are used,

- what, how, with what, how often, with what measuring device and with what precision and where is documented.

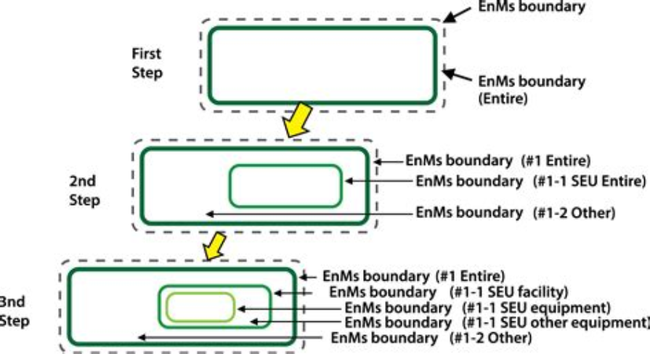

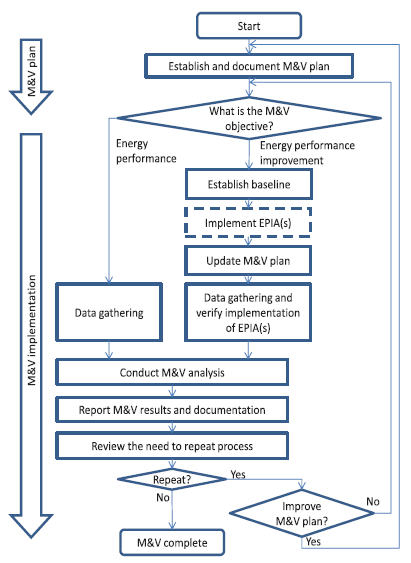

In the complementary energy standard ISO 50015: 2018, a procedure is required for the elaboration of measurement and verification plans (M&V plan) as follows In section 6.6 of the standard, the scope of the energy management system is closed to the extent that the M&V limits must be specifically defined. What should the M&V plan relate to?

- The M&V plan covers the entire company

- The M&V plan only covers parts of the company, which will be excluded ...

As already shown in the scope of the standard, the boundaries must always be documented.

Write a comment